The Role of Technology in Modern Welding Inspection Madison Practices

The Role of Technology in Modern Welding Inspection Madison Practices

Blog Article

Comprehending the Basics of Welding Assessment to Make Certain Top Quality and Security

In the world of contemporary design, welding evaluation stands as a foundation for making sure both the high quality and safety and security of structural developments. The procedure involves a meticulous evaluation of bonded joints, utilizing advanced techniques such as ultrasonic and radiographic testing to find hidden flaws. The competence of licensed inspectors is critical, as they link the space between academic requirements and useful application. Their duty prolongs beyond plain discovery, incorporating the paperwork and communication of searchings for to relevant stakeholders. What are the subtleties of these assessment methods that make them vital for maintaining architectural integrity?

Significance of Welding Evaluation

In the world of commercial manufacture, the importance of welding evaluation can not be overstated. Welding assessment plays a critical role in making sure the honesty, safety and security, and long life of bonded structures. Given the diverse applications of welding in industries such as construction, automobile, aerospace, and shipbuilding, the requirement for strict high quality control steps is critical. Appropriate assessment makes sure that welds satisfy specified requirements and codes, which is vital for protecting against structural failings that might cause devastating consequences.

The procedure of welding naturally involves complex variables, consisting of temperature level, product residential or commercial properties, and ecological problems, all of which can affect the high quality of the weld. A complete evaluation identifies issues such as splits, porosity, and incomplete blend, which can endanger the stamina and reliability of the weld. By identifying these problems early, corrective actions can be taken, therefore reducing the risk of failure and connected costs.

In addition, welding inspection adds to governing conformity, as many industries are regulated by stringent safety criteria and guidelines. Failing to comply with these guidelines can result in economic penalties and legal responsibilities. Ultimately, welding examination not only safeguards physical structures yet also shields human lives and supports market reputations.

Key Welding Assessment Approaches

Although welding evaluation is essential to ensuring the quality and safety of bonded frameworks, it is the certain techniques used that establish the performance of the assessment process. Trick welding evaluation methods can be extensively categorized right into non-destructive screening (NDT) and harmful testing.

Radiographic and ultrasonic testing are advanced techniques that allow examiners to evaluate the inner honesty of the weld. Ultrasonic screening makes use of high-frequency sound waves to find gaps, while radiographic testing uses X-rays or gamma rays to create a photo of the weld's inside. Magnetic particle screening and liquid penetrant screening are surface examination techniques made use of to situate surface area and near-surface flaws. In contrast, harmful testing techniques entail physically damaging or cutting the weld to evaluate its mechanical homes. These thorough evaluation approaches guarantee that welds fulfill industry standards and security requirements, thus ensuring structural stability and efficiency.

Role of Certified Inspectors

Licensed examiners play an essential duty in the welding inspection process, ensuring that all welds follow rigid market requirements and security guidelines. Their proficiency is important in determining problems or irregularities that may compromise the structural integrity of a weld. By diligently examining each weld, licensed assessors aid stop prospective failures that could lead to costly fixings or harmful crashes.

To become certified, assessors need to undergo extensive training and testing, which acquaints them with different welding techniques, materials, and screening methods. This comprehensive expertise allows them to review weld high quality efficiently and make informed judgments concerning their security and reliability. Furthermore, licensed inspectors excel in analyzing blueprints and specifications, making certain that the welding work aligns with the job's design needs.

An essential part of their function is to record their findings extensively, offering a thorough record of the examination process. This paperwork is crucial for traceability and responsibility, offering as an official record of compliance with market criteria. Certified examiners additionally play a vital duty in facilitating communication in between job stakeholders, offering insights and suggestions to improve welding methods and end results. Their payment is essential in keeping high degrees of quality and safety and security in welding procedures.

Tools Made Use Of in Welding Inspection

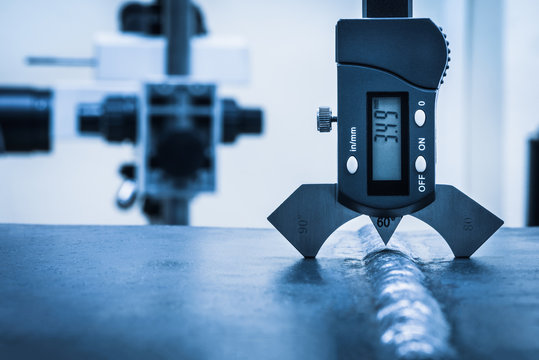

Welding assessors rely upon a selection of specialized devices to do their tasks successfully, making sure each weld satisfies the required standards. Amongst these tools, visual examination help like amplifying glasses and mirrors are fundamental, allowing assessors to very closely take a look at welds for surface defects such as splits, porosity, and undercut. Calipers and fillet weld assesses are important for measuring weld measurements to verify conformity with style specifications.

Advanced devices extend past visual help, including non-destructive screening (NDT) devices. Ultrasonic testing devices are crucial in identifying subsurface problems, utilizing audio waves to reveal inner gaps without compromising the weld's stability. Similarly, radiographic screening employs X-rays or gamma rays to capture photos of a weld's interior, highlighting possible problems.

Magnetic fragment screening read the full info here is an additional crucial tool, particularly for identifying surface area and near-surface discontinuities in ferromagnetic materials. By applying magnetic areas and ferrous particles, examiners can determine problems that might or else be unnoticeable.

Dye penetrant inspection is frequently utilized for non-ferrous products, supplying a contrast-enhanced aesthetic look for surface-breaking issues. Welding Inspection Madison. With each other, these tools make it possible for welding examiners to comprehensively analyze weld quality, ensuring security and reliability in different applications throughout industries

Making Certain Structural Stability

Welding procedures must follow well established standards and codes, such as those defined by the American Welding Society (AWS) or the International Organization for Standardization (ISO) These standards guarantee content that the welds can withstand functional anxieties and environmental variables. Certified and accredited welders play a vital role in this procedure, as their competence guarantees that strategies are applied appropriately, reducing issues such as fractures, porosity, and insufficient fusion.

Post-weld evaluation is an additional vital element of validating architectural integrity. These evaluations verify that the welds fulfill the called for top quality standards, offering assurance of their longevity and reliability.

Conclusion

The basics of welding inspection are crucial for preserving the quality and security of welded frameworks. The use of specialized devices Learn More additionally enhances the assessment process, inevitably protecting human lives and lengthening the lifespan of bonded constructions.

Welding examination plays an important role in making sure the integrity, security, and durability of welded structures.Although welding examination is vital to ensuring the high quality and safety and security of welded structures, it is the details methods utilized that establish the effectiveness of the assessment procedure. Trick welding evaluation techniques can be generally categorized into non-destructive screening (NDT) and devastating testing.Licensed examiners play a crucial role in the welding evaluation procedure, making certain that all welds comply with stringent industry requirements and safety guidelines.The principles of welding evaluation are important for keeping the quality and safety of welded structures.

Report this page